We’ve been in the manufacturing and distribution business long enough to know that catch weight management is critical for so many of our customers.

Effectively managing catch weight is difficult and can have a direct impact on your bottom line and customer satisfaction if not done so correctly.

But managing actual weights is easier said than done.

That’s because without the tools in place to properly account for the actual weight of products, your team is left manually tracking weights or spending too much time and resources tracking these actual weights throughout production.

The result is inefficiency across your core business processes, including Procure to Pay, Plan to Produce and Order to Cash.

Fortunately, there’s systems out there to help.

In this blog, we look at:

- What is catch weight?

- Why is catch weight so important?

- What is the key to managing catch weights?

- How does ERP manage catch weight?

Let’s dive in.

What is Catch Weight?

At a high level, catch weight refers to the actual weight of an individual product. Catch Weight Management is primarily used in food manufacturing (and more specifically in meat, seafood, produce and cheese processing), but is also used by other businesses that convert an original unit of measure to a different one at time of fulfillment and then need to adjust pricing to reflect actual weight.

An example is a porkchop, which is priced based on the weight of the actual piece of meat and not as a single porkchop with a fixed price.

Catch weight items are typically sold by the case and by their actual weights. The weight inside the case may vary from the item’s average weight, and manufacturers and distributors need tools to account for these variations.

Another good example is two blocks or wedges of cheese. Each block will inevitably vary in weight and size depending on how the cheese was broken down during processing. Although both blocks are roughly the same size, the unit price must reflect the actual weight of each product. If there’s a discrepancy between the unit price and the catch weight price, processors risk charging customers too much or losing money.

Why is Measuring Catch Weight So Important?

It’s not easy accurately managing and measuring catch weights. But the importance of it is critical.

In a blog post recently published on FoodBusiness ERP (NexTec’s software solution built in Sage X3 specifically for food and beverage manufacturers), we outlined three reasons why catch weight management is essential for success:

- Accurate pricing

- Improved production

- Buyer satisfaction

Head on over to the FoodBusiness ERP blog to learn more about this.

The Key to Accurately Managing Catch Weights

Many companies come to us using manual processes to manage catch weights. And it’s not surprising. Without the tools in place to automate catch weight management, manufacturers and distributors are left stopping production lines to manually record the weights of every package that comes through.

But as a company grows, so does it’s need for an intelligent solution that automates the capturing, weighing and labeling processes central to managing catch weights effectively.

With such a solution, businesses can ensure pricing accuracy and production efficiency, in turn leading to more satisfied customers and higher sales.

Let’s look at how an automated system for managing catch weights – or an Enterprise Resource Planning (ERP) solution with catch weight functionality built in – works.

Automating Catch Weight with ERP

For those new to ERP software, it works by combining a company’s data, departments and processes into a single system. From there, businesses can streamline operations and get real-time visibility into company-wide data.

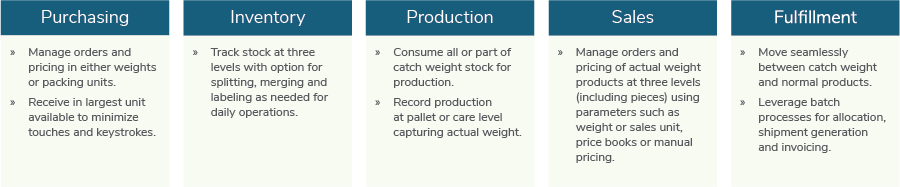

In terms of catch weight management, ERP software integrates every step of the process into core modules of the system. Catch weight products, then, are measured and managed at purchasing, fulfillment, production and shipping. The result is full transparency and ultimate catch weight control.

With an ERP system, users can easily log the weight of products when they are purchased and ensure that weight is tied to it throughout its lifecycle. That’s because ERP utilizes a single, integrated database to manage a company’s operations.

Additionally, ERP software that enables Automatic Data Collection (ADC) functionality allows users to scan barcodes, perform transactions and manage products using a mobile device. This guarantees efficiency and data integrity since shop-floor data is being relayed to the ERP system in real-time.

Why a Flexible Approach is Critical

Not all catch weight management solutions on the market are equal. We work with companies that come to us utilizing legacy systems or proprietary software to manage catch weights but are struggling to do so efficiently. Our consultants help them implement best practices and provide an extra layer of efficiency using software built with their catch weight requirements in mind.

Here’s an example:

NexTec’s catch weight management functionality is built in Sage X3’s powerful ERP platform. Because the solution can inherently manage multiple units of measure, users can be flexible in the way they measure product coming into their facility. This helps minimize overhead and the resources it takes to track each case’s actual weight throughout production.

Instead, the software allows multiple levels of weight tracking when possible, including by pallet, case and piece. For example, at purchasing users can enter product into the solution using the actual weight of the largest unit of measure, such as pallet or case. Then, since the software doesn’t require you to track actual weights in smaller units until required, users can simplify the receiving process and increase efficiency.

When actual product weight at a lower unit of measure is required, the system adjusts the original weight and new field unit accordingly. New labels will also be produced.

Conclusion

It’s clear that accurately managing catch weights is critical. If you’re not doing so effectively, you risk losing money and threatening customer satisfaction.

If you’re worried that your business is not running as efficiently as possible because of manual catch weight processes, it might be time to consider evaluating solutions that automate the many tedious tasks involved in running your manufacturing or distribution business.

Ready to learn more, reach out to us. We’d love to show you what our solutions can do.